Research and development

- Innovation and development work is carried out in five development centers

- Further expansion of external partnerships and collaborations

- Use of digital elements is shortening development times

The aim of research and development work at HUGO BOSS is to offer the best products in the industry and thus to directly contribute to the corporate vision of being the most desirable fashion & lifestyle brand in the premium segment. Hence research and development (R&D) refers to the product development process, which involves the transformation of a creative idea into a marketable product. Innovation and development work is carried out across five development centers in Metzingen (Germany), New York City (United States), Coldrerio (Switzerland), Morrovalle (Italy) and Scandicci (Italy). At the Group headquarters in Metzingen, HUGO BOSS develops the major part of its collections. In doing so, the Company makes use of its technical center to test innovative production methods and produce prototypes. Parts of BOSS Womenswear are designed in New York City. The Coldrerio excellence center is responsible for the development of the product groups shirts, ties and knitwear and also for the design and development of shoes, leather accessories and bodywear. High-quality shoes and leather accessories are developed at the Morrovalle and Scandicci sites.

Partnerships and collaborations

HUGO BOSS increasingly relies on partnerships and collaborations with designers, artists and organizations around the world. In this way, a creative impetus is to be generated by accessing external knowledge and ideas on the one hand and driving forward innovations on the other. On the occasion of the 60th birthday of Michael Jackson, for example, the Company developed a limited “BOSS x Michael Jackson” collection in 2018. In this context, the famous white BOSS suit that Michael Jackson is wearing on the cover of his legendary “Thriller” album was produced again in a strictly limited edition. For the 2018 Christmas campaign, BOSS also entered into a collaborative project with the artist, product designer and author Jeremyville. This resulted in the creation of the limited collection “BOSS x Jeremyville”, in which the clear-cut BOSS design meets youthful playfulness. As part of the collaboration with Porsche in Formula E, a “Porsche x BOSS” collection was recently developed. Design elements of the innovative Porsche concept car “Mission E” served as a source of inspiration. The collection consists mainly of sporty styles from the casualwear division, yet also modern tailoring. The collection will be available in selected stores and online as of March 2019.

Product innovations were driven forward by BOSS in the past year, in particular for its athleisurewear. In collaboration with partners, a lot of work was put into intelligent golf products that record movements during a game of golf. Using a mobile app, the recorded data can then be analyzed, with the aim of developing a product for the customer that has been optimized in terms of functionality. The development up to a ready-for-sale product is to be continued in 2019.

In 2018, sustainability once again played a crucial role in product development. An exclusive selection of premium quality pieces made from merino wool whose origin is completely traceable was developed. The collection includes six complete looks that will be available with the 2019 fall collection. Sustainability

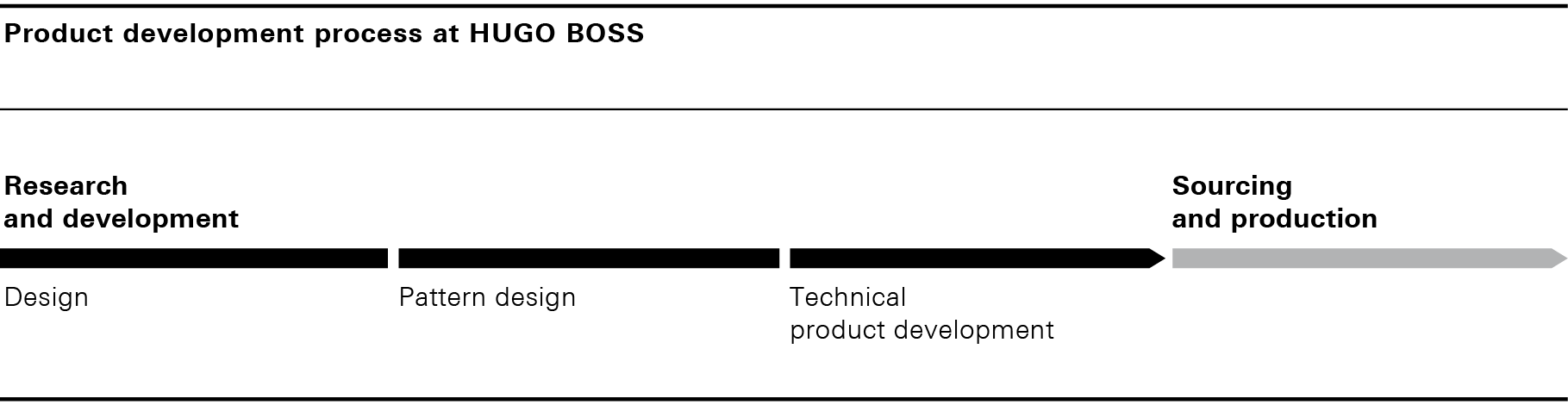

Product development process

The creative idea marks the beginning of the product development process. A collection theme is determined taking into account the brand strategy and brand values as well as an analysis of global mega and fashion trends. The transformation of the creative idea and designs into specific collections also takes account of the sales success of earlier seasons as well as factors relevant to the individual markets, such as regional purchasing power, climate, fashion preferences and the prevailing market environment.

In a second step, the design teams’ creative ideas are tailored in the pattern design phase. Technical product development then turns the models into prototypes and tests their suitability for the industrial production process. In order to become more flexible and faster in the development of its collections and accelerate the product development process further, HUGO BOSS is focusing on continuing to drive the digitization of the product development process. Digital prototypes are increasingly being used in this context. The development time for the HUGO brand’s first digitally developed assortment was thus shortened from eight months to six weeks. In the coming years, this concept is to be expanded further and the share of the digitally developed assortment will continue to increase. A digital fabrics and trimmings library was also established for the HUGO brand in 2018. It contains a selected number of fabrics and trimmings that are available at all times and whose use was already successfully tested in previous collections.Group Strategy, Digital Transformation of the Business Model

After the prototype has been assembled, a sample collection is produced for presentation and sale to wholesale partners. A digital showroom was used for the first time in 2018 to sell HUGO collections to wholesale partners in Europe and the Americas. It will also be used for the BOSS brand in 2019. Following the sale of the collections to wholesale partners, collections then go into production and are shipped to the wholesale partners as well as to the Group’s own retail stores.

The Spring/Summer 2019 collection of BOSS is themed “California Breeze.” The collection was inspired by the coastal cities of California and the relaxed lifestyle on the Pacific coast. The seamless transition between beach and city life shaped a collection that combines modern design with easiness and summeriness. Complete looks in pastel shades emphasize the easiness of the collection. In addition, intense colors such as yellow and orange provide color accents. The Spring/Summer 2019 collection of HUGO tells the story of a Berlin geek who works hard during the day and parties in a techno club at night. HUGO is inspired by this “mixmaster” who consciously chooses a creative and daring clothing style and is ready to combine styles from different decades. The combination of natural fibers and synthetic materials accentuates this contrast. Oversized looks and the use of the HUGO logo also characterize the collection.

R&D key figures

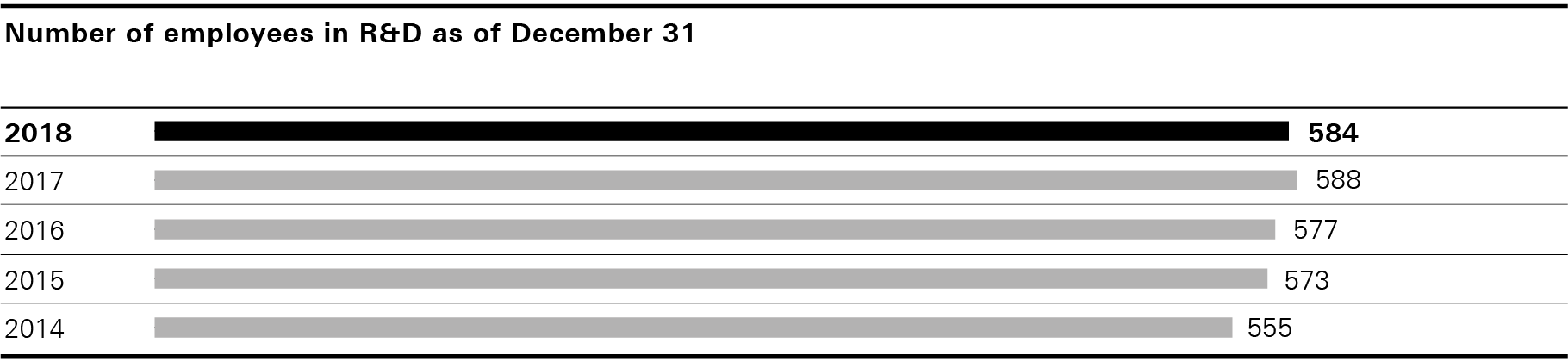

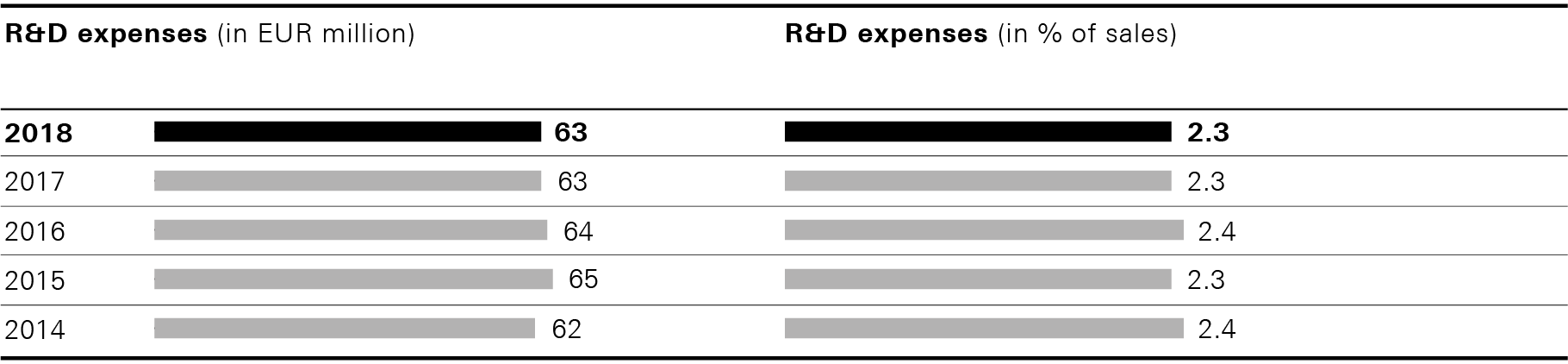

The creative and development departments of the HUGO BOSS Group are staffed by skilled fashion designers, tailors, shoe and clothing technicians and engineers.

At 71%, personnel expenses accounted for the bulk of R&D expenses last year (2017: 70%). The rest is primarily composed of other operating expenses. In 2018, R&D expenses were again mostly recognized as incurred. In addition, production-related development expenses are included in the cost of conversion of inventories. No development expenses were recognized as internally generated intangible assets due to the short product life cycles.